Cette publication est également disponible en :

Français

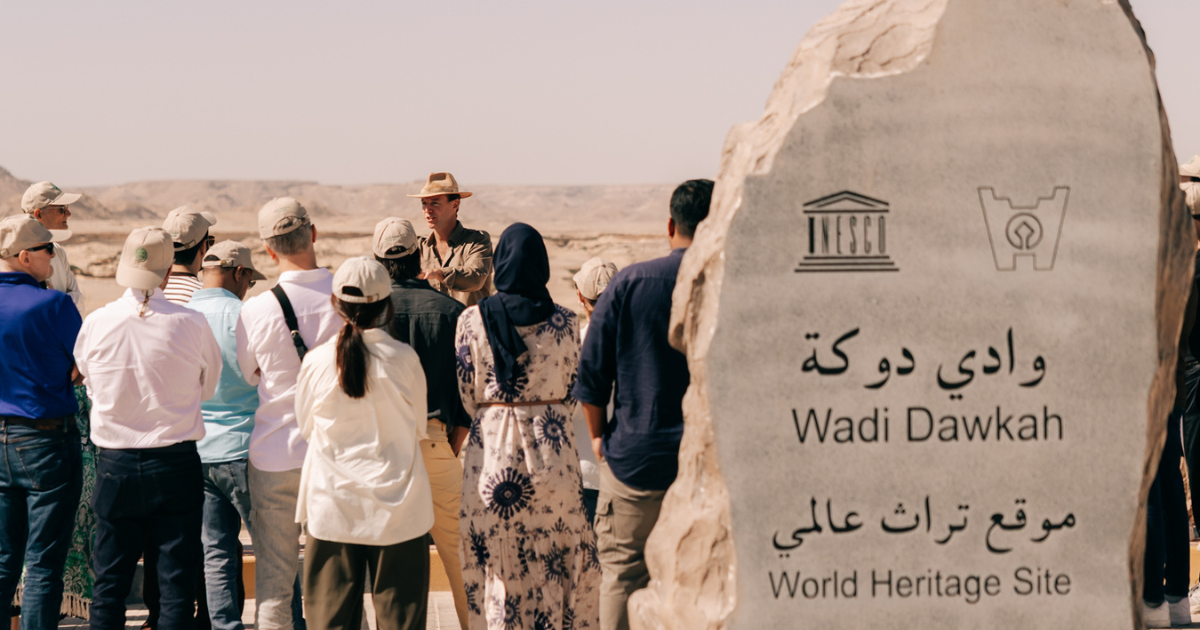

Today, Australia has overtaken India as the largest producer of sandalwood, where the sacred tree originated. As the world’s leading sandalwood exporter, Quintis has built a long-term development strategy to ensure both consistent yields and prices.

Editorial partnership

A bird’s-eye view of their site presents a breathtaking panorama, with plots of trees stretching as far as the eye can see, crisscrossed by ochre roads. On the ground, men and women in orange shirts, wide-brimmed hats and Bermuda shorts work in the shade of the branches. These workers, placing sensors on the trunks to measure daily growth and monitoring the irrigation system, are employed by Quintis, the world’s leading producer of white sandalwood. “With 5.5 million trees over 12,000 hectares, our company supplies the fine fragrance, cosmetics, aromatherapy, traditional medicine and furniture sectors across the globe, in the form of logs, wood chips, powder and essential oil,” explains Vanessa Ligovich, director of marketing. Of the three species used in perfumery, Quintis grows and distills primarily Santalum album, originally from India, and also distills Santalum spicatum, native to Australia.

The former has been grown locally since 1999 and is descended directly from Indian plants from the Mysore region, the area with which it is historically and culturally linked. It is nicknamed “King of Woods” and has acclimatized easily to northern Australia, which shares the same tropical climate as southern India. Its essential oil has a high alpha- and beta-santalol content (70% to 90%), guaranteeing its beneficial properties and fine fragrance. It has a sweet scent which combines woody and creamy notes.

The latter native variety grows in the semi-arid conditions of southwestern Australia. This “Prince of Woods” contains less alpha- and beta-santalol (20% to 40%), while its olfactory profile has a greener, fresher top note and a more earthy, terpenic and smoky base and is used less frequently in fine fragrances.

Plantations for a sustainable future

Quintis sandalwood is therefore 100% locally produced, and the company has infrastructures spread over three Australian sites. It has two units in the north, one in Kununurra, where cut wood is processed, and a plant nursery in Katherine. Then some 4,000 kilometers away, in the southernmost part of Western Australia,it has a distillation plant in Albany. It also has a warehouse in Xiamen, China, as the country continues to be a major consumer of sandalwood products, particularly for traditional medicine. Chinese culture is not alone in its therapeutic use of sandalwood: It is also prized by two Aboriginal tribes for its antiseptic and anti-inflammatory properties. Indeed, it has already been cultivated in Australia by the Noongar and the Martu, albeit on a far more modest scale than that of modern plantations. Today, Quintis claims to have planted enough Indian sandalwood to satisfy customer demand for several decades to come. Founded in 1997 as Tropical Forestry Services (TFS), the company expanded its production capacity when it acquired the specialist essential oil distillers Mount Romance in 2008. It adopted its current name in 2017, adding “quint” from the word “quintessential” to the first letters of the words “Indian” and “sandalwood.” Their technical innovations have expanded over the years, for instance pioneering natural techniques to develop trees whose heartwood (the central part of the trunk used for distillation) gives a yield that is up to 18% higher. All Quintis products are produced without the use of growth hormones or genetic modification.

A measured approach to water

In the field, employees work with environmentally friendly practices, with no recourse to artificial ferti lizers or hormones. “Two-thirds of our plantations have a drip irrigation system, which uses up to 75% less water than conventional watering techniques,” says Vanessa Ligovich. Probes sunk to varying depths extend throughout the plots to constantly monitor the water supply. Another water-saving measure is the pruning of trees to ensure their foliage consumes as little water as possible. Renewable energies are at the heart of the process, accounting for 40% of energy consumption. At the Albany site, the biomass boiler uses waste wood from the production line. The heat it generates provides the steam for distillation. All of this reduces fossil fuel emissions by 65% each year.

In 2011, the company installed a system at the facility which uses bacteria to purify the water, before reusing it in the cooling towers. This initiative earned Quintis the “Champion Award” from the Western Australian Water Corporation. Given that it takes 15 years for a tree to reach adulthood, all of these measures add up to ensure long-term success. A few years ago, the lack of raw materials drove up the price of sandalwood. “Currently, the mini mum cost of 1 kilo of essential oil is $2,100 to $2,500. We expect a sustainable return to normal, as supply volumes are now more reliable,” explains Ligovich. Such stability is in everyone’s interest, including that of the end consumer.

—

This text is from the book published by Nez From Plant to Essence – A World Tour of Fragrant Raw Material (June 2021)

Comments