Cette publication est également disponible en :

Français

As a chemistry graduate, Frédéric Badie first joined Mane to train in formulating natural ingredients. From there he went to Charabot, where he worked on olfactory and analytical control before becoming a perfumer at CAL-Chauvet. He is currently R&D director at Payan Bertrand.

—

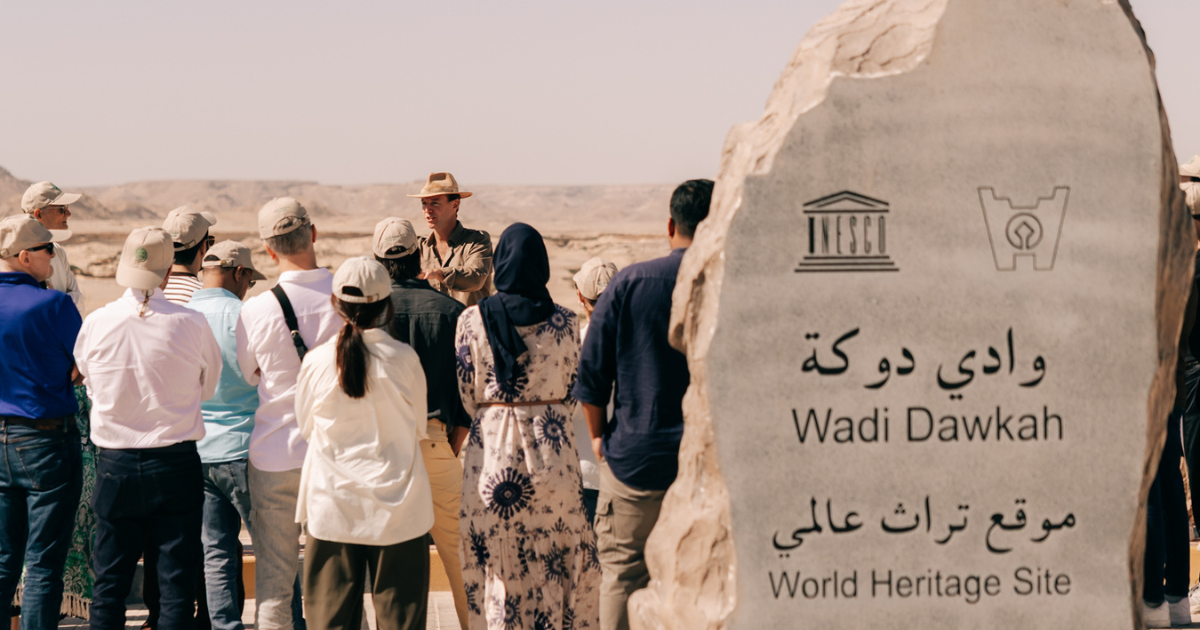

Interview from the chapter dedicated to the frankincense, in the book From Plant to Essence – A World Tour of Fragrant Raw Material (see below)

—

What is your relationship with frankincense?

I’m particularly fond of this raw material, as it is one which enables me to showcase the many ways in which a single ingredient can be used. I often use it to illustrate the wealth of possibilities available to perfumers.

How does its processing journey begin?

Distillation begins at 6 a.m. Some 200 kilos of gum will be distilled each day in 5,000-liter stills, then unloaded in the evening to prepare for the next day’s distillation. One vat load after another will be processed, turning out 4 metric tons of gum per month, with an overall yield of anywhere between 6 and 8%. A blend will be made based on an olfactory profile of the harvest in order to uphold our consistent quality standards.

The tour continues…

Moving on, here we come to the dry distillation area in which the gum is processed in small batches; it is processed pure and without water in an ovoid reactor whose temperatures can reach up to 300°C. Vacuum distillation (also known as destructive distillation) brings subtle facets to its fragrance, from balsamic to smoky leather notes. Then, we go down to our extraction workshops where the gum is processed with three washes, using hexane or alcohol to create either a clear, pure absolute or a warm, balsamic resinoid with a dark brown hue. Finally, our tour ends in the molecular distillation workshop, where we create clear and liquid extracts

What are your house specialities?

Oil fractionation enables us to obtain “frankincense hearts” with cleaner notes, free of terpenic notes, such as pinenes and alpha-thujenes. Ultimately, Process e is a sophisticated approach to formulation that involves blending different concentrated frankincenses to create a balance between the fresh, balsamic, resinous facets and the leathery and smoky aspects.

- More about Payan Bertrand: https://www.payanbertrand.com/en/

—

This interview is from:

De la plante à l’essence – Un tour du monde des matières à parfums

From Plant to Essence – A World Tour of Fragrant Raw Material

(Français-English), Nez éditions, Collectif, 2021, 45$/30€

- Available for France and international: Shop Auparfum

- Available for North America: www.nez-editions.us

Comments