Cette publication est également disponible en :

Français

On the occasion of the International Exhibition of Raw Materials for Perfumery (SIMPPAR) which will take place on May 31 and June 1 in Paris, we invite you to discover a series of articles originally published in the book From Plant to Essence. A World Tour of Fragrant Raw Materials. Let’s start with Firgood [1]Firgood is a Firmenich trademark. extraction method, a natural revolution at the Swiss composition house specializing in flavors and fragrances. Firmenich has indeed set up a unique microwave-assisted extraction facility in Grasse, and has unveiled its first Firgood ingredients two years ago.

For over six years now, a team of researchers has been working on a secret project within their Grasse facility. It involves the development of a brand-new extraction method to tackle a two-fold challenge: firstly, the need to process ingredients which have hitherto been difficult to extract, and secondly, the urgent need for extraction methods which are more sustainable and which use less energy and fewer resources. “All of our progress over the last few years has helped us turn a theoretical ideal into reality: an extraction method which doesn’t involve a solvent,” says Xavier Brochet, Global Head of Natural Product Innovation at Firmenich. “We have just passed a milestone: After lab trials, we are scaling up to industrial volumes.”

Using only the water contained in the ingredients

The method consists of applying electromagnetic frequencies to a fresh biomass. When exposed to these, the vibration of O-H bonds produces friction that induces a rise in temperature. The constituting water begins to warm up, inducing cell disruption and conveying the aroma compounds. “So no solvent is required other than water, which comes mainly from biomass itself,” explains Sophie Lavoine, Director of Naturals Innovation at Firmenich. “This innovation is the culmination of advances in extraction technology, which have always been moving toward safer and greener solvents: Benzene was replaced by hexane, then supercritical CO2 and now the water in the ingredients themselves.”

The Firmenich teams have accomplished a considerable feat of engineering in scaling up production while keeping costs down. Indeed, having started at 100 to 200 kilograms, capacity has now reached 1 metric ton. The key to achieving this is continuous flow production, using an “open” process, as opposed to batch production. The biomass is moved along on a conveyor belt before entering a tunnel where it is heated. All energy expended is optimized and strictly calibrated to the quantity of biomass being processed so as to avoid any overcooking and to preserve its organoleptic properties. Gravity separation enables the collection of the final product.

Three product types are being launched under the new Firgood brand to further enhance the palette of the composition house’s perfumers and flavorists. First of all, a stock solution, or hydrolate, contains all of the polar aromatic fraction (composed of less lipophilic molecules) of the product in the water-soluble phase. From this stock solution, a second product is created using physical methods for the cold concentration of aromatic fractions. The water is replaced by another solvent, alcohol for example, for use in perfumery. Finally, an essential oil can also be obtained by decanting from the stock solution, if its oil content is sufficient. This method is suitable for spices, for example.

Creating a healthier planet and a more natural fragrance

This extraction method offers many advantages, notably lower energy consumption. Moreover, the process makes the recovery of waste residues much more straightforward than that of traditional techniques. As they do not contain any solvents, they can be recycled or put through other extraction processes, such as supercritical CO2 extraction, to render other extracts with complementary profiles. “Indeed, this is focused on fat-soluble fractions and on aldehydes. SFE Vanilla [obtained by supercritical fluid extraction] will be rich in vanillin, while the Firgood extract will reveal acids, phenols, guaiacol and its derivatives,” explains Sophie Lavoine.

The huge range of applications justifies the risk of this major investment, as it enables flowers, fruits, spices, vegetables and roots to be processed, in the form of fresh or even re-humidified material. The speed of the process helps avoid undesirable side effects, including cooking, oxidation or polymerization, which can occur when the material undergoes prolonged thermal or chemical shock. The new extracts will be made available to the fine fragrance, hygiene and flavorings sectors at an affordable price range for the market, considering their olfactory and technical qualities. The first products revealed in 2021 – Firgood ginger, pear and bell pepper – will soon be joined by other ingredients derived from flowers, fruits, teas and coffees.

“We look back with humility on this journey, enhanced by many outside initiatives that have contributed to this progress. Thanks to this versatile technology, which we have been able to adapt to each ingredient, we can now envisage broadening the production of alternative extracts to our entire range of natural ingredients,” concludes Xavier Brochet. “We are also proud to be contributing to the continued evolution of extraction methods that have been defining features of perfumery’s long history, as well as to the influence and prestige of the Grasse region.”

This article was first published in From Plant to Essence. A World Tour of Fragrant Raw Materials, edited by Nez.

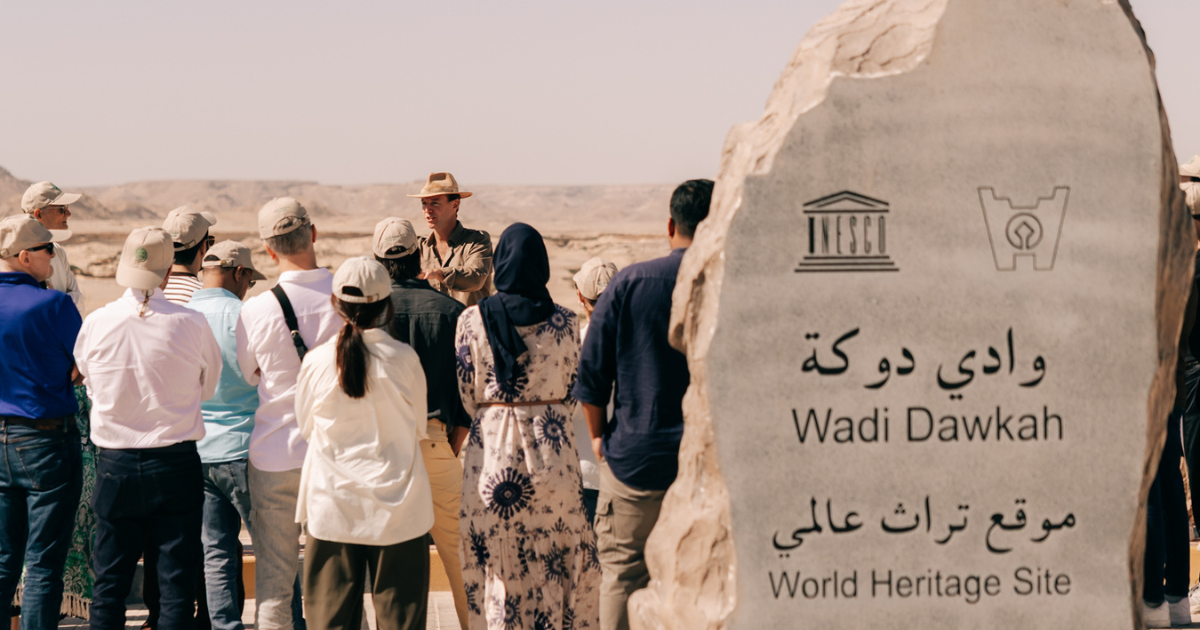

Main visual: ©Agence Odds for Firmenich

Notes

| ↑1 | Firgood is a Firmenich trademark. |

|---|

Comments